As I was having major progress with Pronterface and SFACT I thought I had better build a good latest release version rather than the stable distribution version I was currently using, not expecting much other than an improved pronterface GUI I was stunned to discover a marked increase in quality again, a couple of large prints later (still trying to eliminate warp) and I had the idea that now the machine is “Working” I could test increasing the X/Y speed a little moving away from the extreamly slow speeds I had set so that I could see what was going on.

So I doubled the Main feed rate to 20 and the perimeter Feed Rate to 20 and the travel rate to 40 (I chose these values as they are the minimum that pronterface will allow you to select using the dialog rather than typing in specific values)

And to my amazement I again witnessed a marked improvement in quality especially when printing objects with bridges in them. (obvious really as it gives less time for the filament being printed to sag before arriving at the far side of the bridge)

Must be careful not to push the speed to much as I know that the machine skips badly when using main feed rates of 60 or so as these were the defaults I had to ditch to get the printer to work in the first place, also the Darwin is using resin cast bushes as far as I can tell, I want to replace these with linier bearings ASAP so I can really start to play with the speed of the printer and explore its limits.

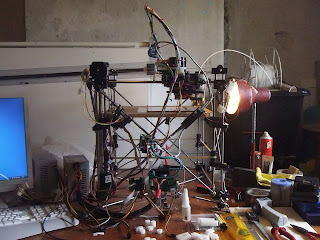

There are a host of mechanical issues with the Bootstrapped Darwin detailed below

1)

I still have major mechanical issues with the Darwin Z axis design,

some parts on thingiverse should address this (reference parts)

2)

The X & Y Carriages are using what look like cast resin bushes

these need replacing with linier bearings

3)

The Y Axis top end corner mounts are also using cast resin bushes

other upgrades on thingiverse will address this

4)

The Z axis uses cast resin drive gears (4 of them) for which I have

no printable replacement! So this is a fairly major flaw as if one of these fails

printing stops dead! Need to replace these with real metal gears as the drive

belt is a 2.5 mm type and so as far as I know can’t be printed .

5)

The Z axis drive belt is a mess and needs replacing (teeth missing

2 super glued joins) after a breakage, I won’t attempt this until I have some

of the Z axis upgrades printed (namely the 608 corner bearing holders,

reference part) as this will change the

length of the timing belt.

6)

The Z axis drive linkage is a bodged piece of petrol hose with 2

hose clamps this needs a printable Z linkage (again I am not going to attempt

this until the Z axis corned screw threads

have been fitted with 608 bearing housings and made true and properly square)

amazingly this bodge seems to be holding up remarkably well considering how

long it has been driven.

7)

The X axis idler is again a cast resin bush, can’t find any upgrade

that addresses this but I don't think it would be difficult to replace with a

608 bearing and 2 large wide washers as used in the Prusa design. I will need

to address this one fairly soon as the current resin bush makes creaking sounds

( I think it has cracked down one side and this is causing the creaking sounds,

it will probably fail soon prompting me to upgrade to the bearing & washer solution)

8)

It would be good to move the electronics into more stable positions

as one of the stepper drivers is currently floating in free air and moves a

little as the Y axis moves, this will eventually lead to copper wire fatigue

and failure. Also the stepper that drives the extruder motor is literally zip

fastened to the bundle of wires that feed the extruder controller it needs mechanically

fixing to the same bracket the extruder controller is mounted on.

9)

Z axis needs a proper belt tensioner, currently bodged with my

solder sucker zipfastned to a lump of wood solution. Can’t seem to find any

Darwin style belt tensioners on Thingiverse might need to email Adrian Boyer on

this one and beg the .stl’s for his design.

10)

The Gregs accessible wades geared extruder is crudely bodged onto

the Darwin “Quickfit dock” and again I can’t find any stl’s for the quickfit

dock on thingiverse or anywhere else on the web will mention this in the email

to Adrian to see if I can get that one as well.