Ordered a “Gregs accessible wades geared extruder” from eBay for about £21.00 for the 4 printed plastic parts plus a bag of mechanical fixings to fit, a bargain in my opinion, after assembling it and following the online instructions on how to connect it to the Gen 3 setup I have, a short frenzy of soldering & butchering of some old PC CD/Audio cables I had laying around and suddenly things had evolved.

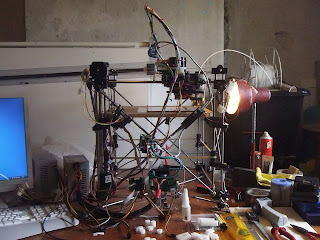

Gregs accessible wades geared extruder

Seeing as pronterface is turning out to be the way forward I found an followed another of Spacexula’s excellent you tube videos on cow to calibrate your “E steps per mm” for both the 3 axis and extrusion length, this cured the size of print issue as the Mendel axis defaults were almost exactly half what they should have been for the Darwin style steppers, the e steps for the extrusion length are set low deliberately to allow you to calibrate for any style of extruder, and after calibrating all 4 of these steps.

Began tinkering with the SFACT slicer settings in Pronterface and discovered that there are loads of settings I am going to have to get my head around.

Now the system was extruding reliably I was much more able to see exactly what was happening and after another print of the widebar I let it run and voila on the second and third layer things were starting to work, I was beginning to suspect that it was skipping steps on the Y axis after the first layer, lowered the speed setting considerably in SFACT and bang we were printing!

The next print of the widebar and finaly it looked like I may have cracked it, after letting it run my heart sank again as I realised that the Z Axis was not moving, it was skipping/stalling somehow, a long web read later and I had an inkling that it may be something to do with the “limit” settings in SFACT apparently as I am using old firmware Pronterface can’t limit the Z axis speed, Sprinter and Marlin firmware is supposed to cure this issue (will have to investigate these firmware’s) as they allow the Z axis speed to be controlled by host program (still not sure I get this completely but hey at least the Limit tab in SFACT should allow me to get the Z axis moving.

A few more attempts at a Wide bar and I discover that I need to set my Z axis speed limit to 1mm/min not the 5mm/min default value and at last the z axis begins to move as expected.

To my amazement the Wide bar prints perfectly!

To excited to contain myself I now find myself cruising Thingiverse for the first time in the realisation that I now have a “working” 3D printer.

Downloaded a load of calibration objects, Darwin parts/upgrades and of course a “Gregs accessible wades geared extruder”

Here are the SFACT value’s I have discovered work for my particular Bootstrapped Darwin setup

Speed - all feed rates = 10, all flow rates = 1.5

Altivate Limit - all feed rates 1.0

Cool - activate cooling if small or thin

parts (Cool on large parts causes warp)

Raft - Deactivate Raft

Carve - extrusion width 0.5

I spent the next month attempting all of

the printed plastic parts for a Prusa Mendel, (the 1st child printer)

discovering that I will probably need fans, maybe a heated bed (if I want to

print ABS)

Printing parts at last!

Small cogs look good on the side being cooled by the fan but the far side obviously needs cooling also as it is a mess

After much frustration messing about with

fans I had the idea of just increasing the number of small parts printed

simultaneously, then as far as the printer is concerned this is a large part

and therefore gives plenty of time to cool between layers.

Tested this theory by printing 2 small

cogs at the same time using the multiply function on SFACT and hurrah it worked

a treat

Large parts still seem to suffer from

some warping this may be due to the fact that my spare room where I am running

the Darwin is very cold and draughty < 10 degrees C, I have a plan to move

the machine completely out of the house and into my workshop (which is

currently an impromptu builders yard) but this will take a lot of clearing and

reorganising.

I still have major mechanical issues with

the Darwin Z axis design, some parts on thingiverse should address this

(reference parts)

No comments:

Post a Comment